Application case of DTH hammer in extremely hard rocks in South Africa

If you are interested in our products, Please get in contact with us .

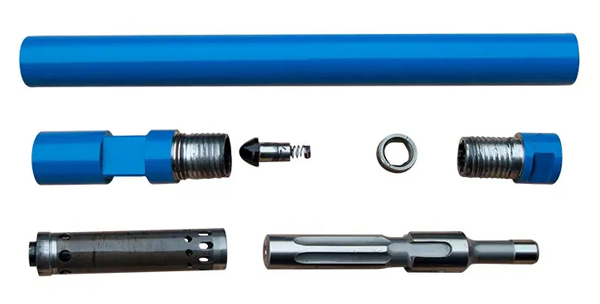

E-mail: sales@sdkdrillingtools.com Chat Line Send InquiryThe application cases of SHANDIKE DTH (Down The Hole) hammer in extremely hard rocks mainly come from the fields of mining, tunnel excavation, and infrastructure construction. Here are some typical application cases:

1. Mining:

-South African gold mines: South African gold mines are one of the hardest ores in the world. The DTH hammer performs well in this extremely hard ore, effectively breaking rocks and improving mining efficiency.

-Australian iron ore: Australian iron ore has a high hardness, and DTH hammers are widely used in the mining of these ores, significantly improving drilling efficiency and reducing drill bit wear.

2.Tunnel excavation:

-Hard Rock Tunnels in Norway: Many tunnel projects in Norway involve extremely hard granite. The DTH hammer performs well in this environment, effectively breaking hard rocks and ensuring the smooth progress of tunnel construction.

-The Qinghai Tibet Railway Tunnel in China: In the Qinghai Tibet Railway tunnel project, facing the challenges of high altitude and extremely hard rocks, the DTH hammer is widely used in tunnel excavation, significantly improving construction efficiency.

3.Infrastructure:

-Infrastructure construction in Dubai: Many large-scale infrastructure projects in Dubai, such as subways and underground pipeline projects, involve extremely hard rocks. The DTH hammer played a crucial role in these construction projects, ensuring the smooth progress of the projects.

Hydroelectric power station construction in Brazil: Some hydroelectric power station construction projects in Brazil require excavation of tunnels and construction of dam bodies in extremely hard rocks. The DTH hammer is widely used in these projects, improving construction efficiency and engineering quality.

These cases demonstrate that the application of SHANDIKE DTH hammer in extremely hard rocks can not only improve drilling efficiency, but also significantly reduce drill bit wear and drilling costs, thus gaining widespread recognition and application worldwide.

Send us a message

You can also send a message to us by this email sales@sdkdrillingtools.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!